Embark on a fascinating journey into the realm of cajas de carton book in english, where we unravel the intricate world of cardboard boxes. From their diverse types and materials to their customizable designs and sustainable impact, this guide provides a comprehensive exploration of these ubiquitous packaging solutions.

Delving into the intricacies of cardboard box production, we examine the materials used and the meticulous process of cutting, folding, and assembling these versatile containers. Discover the myriad customization options available, including custom designs and branding strategies, empowering businesses to create distinctive packaging that reflects their brand identity.

Types of Cardboard Boxes

Cardboard boxes come in a wide variety of shapes, sizes, and strengths to meet the diverse needs of various industries and applications. Each type of cardboard box serves a specific purpose, ensuring the safe and efficient transportation and storage of products.

Corrugated Cardboard Boxes

Corrugated cardboard boxes are the most commonly used type of cardboard boxes. They are made from three layers of paperboard: two flat liners on the outside and a corrugated medium in the middle. The corrugated medium provides strength and cushioning, while the flat liners protect the contents from moisture and dust.

Corrugated cardboard boxes are available in a variety of sizes and styles, including:

Regular slotted containers (RSC)

These are the most common type of corrugated cardboard box. They have four flaps that meet at the top and bottom of the box, and they are held together by tape or glue.

Full overlap containers (FOL)

These boxes have flaps that overlap on all four sides, providing extra strength and protection.

Half-slotted containers (HSC)

These boxes have flaps that overlap on two sides, making them easier to open and close.

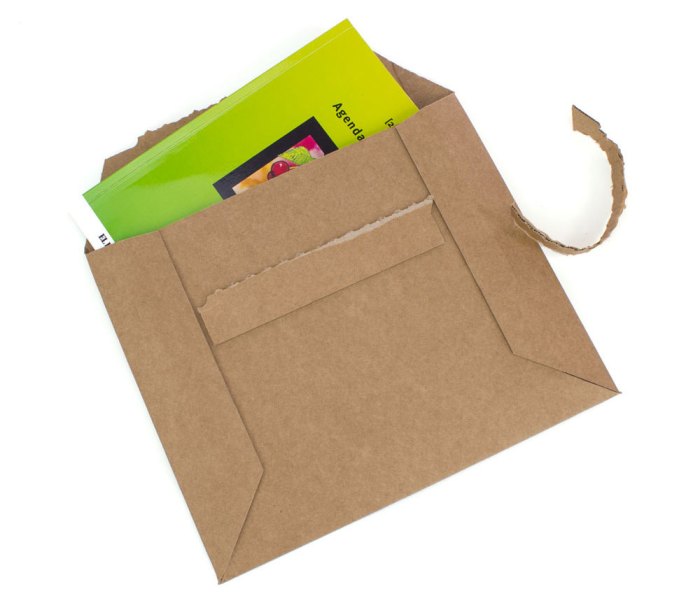

Die-cut boxes

These boxes are custom-made to fit specific products, providing a snug fit and maximum protection.

Solid Fiberboard Boxes

Solid fiberboard boxes are made from a single layer of thick, durable paperboard. They are stronger than corrugated cardboard boxes, but they are also more expensive. Solid fiberboard boxes are often used for heavy-duty applications, such as shipping machinery or electronics.

Folding Cartons

Folding cartons are made from a single sheet of paperboard that is folded and glued into shape. They are lightweight and easy to assemble, making them ideal for packaging small products, such as food, cosmetics, and pharmaceuticals.

Rigid Boxes

Rigid boxes are made from a thick, sturdy paperboard that is covered with a decorative material, such as paper, fabric, or leather. They are often used for packaging luxury items, such as jewelry, watches, and perfumes.

In English, cardboard boxes are commonly known as “cardboard boxes.” To enhance your understanding of the subject, I recommend taking a look at the unit 2 ap psych practice test . It provides valuable insights and practice questions that can aid in your preparation for the AP Psychology exam.

Once you’ve completed the practice test, return to the topic of cardboard boxes and explore its various applications in packaging and storage.

Materials and Construction

Cardboard boxes are made from various materials and undergo a specific construction process to achieve their desired shape and functionality.

The primary material used in cardboard box production is corrugated cardboard. Corrugated cardboard consists of three layers: two flat linerboards on the outside and a fluted medium layer in between. The fluted medium provides strength and cushioning, while the linerboards protect the contents of the box.

Cutting

The cardboard is first cut into the desired shape and size using a die-cutting machine. Die-cutting involves using a sharp metal die to cut the cardboard with precision.

Folding

After cutting, the cardboard is folded along pre-scored lines to form the basic shape of the box. The pre-scored lines are created during the die-cutting process.

Assembling

The final step is assembling the box by gluing or taping the flaps together. Some boxes may also have additional features, such as handles or inserts, which are added during the assembly process.

Customization and Design

Cardboard boxes are not just for storage and protection anymore. They have become a versatile and customizable marketing tool that can help businesses make a lasting impression on their customers. With a wide range of customization options available, cardboard boxes can be tailored to fit any need, from simple branding to elaborate works of art.

Custom designs can be used to create boxes that are both functional and visually appealing. For example, a bakery might use a box with a window to showcase their delicious pastries, while a clothing store might use a box with a unique shape to stand out from the competition.

Branding, Cajas de carton book in english

Branding is an important part of any business, and cardboard boxes are a great way to promote your brand. By incorporating your logo, colors, and other branding elements into your box design, you can create a cohesive and recognizable brand experience for your customers.

Sustainability and Environmental Impact: Cajas De Carton Book In English

The environmental impact of cardboard boxes is a crucial consideration in today’s eco-conscious world. Understanding the environmental consequences of their production, use, and disposal is essential for making informed choices.

Cardboard boxes are primarily composed of paper, a renewable resource derived from trees. However, the production of paper involves processes that consume energy and water, contributing to greenhouse gas emissions and deforestation. Additionally, the use of chemicals in the manufacturing process can have detrimental effects on the environment.

Recycled Cardboard

Recycling cardboard boxes significantly reduces their environmental impact. By reusing existing materials, the need for new paper production is minimized, conserving natural resources and reducing energy consumption. Recycled cardboard boxes are often made from post-consumer waste, diverting it from landfills and promoting a circular economy.

Biodegradable Materials

Cardboard boxes made from biodegradable materials, such as cornstarch or wheat straw, offer a sustainable alternative to traditional cardboard. These materials decompose naturally over time, minimizing their environmental footprint. Biodegradable cardboard boxes are particularly beneficial for packaging products that are sensitive to moisture or require composting after use.

Reducing Environmental Footprint

- Choose cardboard boxes made from recycled materials.

- Opt for biodegradable cardboard boxes when possible.

- Reuse cardboard boxes for storage or shipping.

- Properly dispose of cardboard boxes by recycling or composting them.

- Consider using alternative packaging materials with a lower environmental impact, such as reusable containers or biodegradable packaging.

Applications and Uses

Cardboard boxes are ubiquitous in various industries and applications, offering numerous advantages due to their versatility, durability, and cost-effectiveness.

In the retail sector, cardboard boxes serve as primary packaging for a wide range of products, from electronics to clothing, ensuring protection and ease of transportation. E-commerce has witnessed a surge in the use of cardboard boxes, providing secure packaging for online orders and facilitating efficient shipping and delivery.

Manufacturing

In the manufacturing industry, cardboard boxes play a crucial role in packaging and transporting components, parts, and finished goods. They offer protection from damage and contamination, ensuring the integrity of products during storage and transit.

Storage and Organization

Cardboard boxes are extensively used for storage and organization in various settings, including homes, offices, and warehouses. They provide a convenient and space-efficient way to store and retrieve items, keeping them protected and organized.

Market Trends and Innovations

The cardboard box industry is constantly evolving, driven by advancements in technology, changing consumer demands, and environmental concerns. Market trends and innovations are shaping the future of cardboard boxes, making them more sustainable, customizable, and versatile.

One notable trend is the increasing demand for sustainable packaging solutions. Consumers are becoming more environmentally conscious, and they prefer products that are packaged in eco-friendly materials. As a result, manufacturers are developing cardboard boxes made from recycled materials, biodegradable inks, and water-based adhesives.

Innovative Designs and Technologies

Innovative designs and technologies are also transforming the cardboard box industry. Die-cutting and printing techniques are becoming more sophisticated, allowing for the creation of complex and visually appealing boxes. Digital printing, for example, enables manufacturers to print high-quality images and graphics directly onto cardboard, eliminating the need for labels or stickers.

Emerging Applications and Advancements

Cardboard boxes are finding new applications in various industries. For instance, in the e-commerce sector, corrugated cardboard boxes are widely used for shipping products safely and efficiently. In the healthcare industry, cardboard boxes are used for packaging medical supplies and equipment.

Advancements in materials science are also contributing to the development of new types of cardboard boxes. Lightweight and durable cardboard grades are being developed to meet the demands of different industries. These advancements are making cardboard boxes more versatile and suitable for a wider range of applications.

Question Bank

What are the different types of cardboard boxes?

Cardboard boxes come in various types, including corrugated boxes, folding cartons, rigid boxes, and specialty boxes, each designed for specific applications.

How are cardboard boxes constructed?

Cardboard boxes are typically made from corrugated cardboard, which consists of multiple layers of paperboard glued together, providing strength and durability.

Can cardboard boxes be customized?

Yes, cardboard boxes can be customized in terms of size, shape, design, and printing, allowing businesses to create unique and branded packaging solutions.